Need assistance in the design or development of your part?

Our team of plastic extrusion experts will work with you to ensure you find the right material for your extrusion’s usage. With over 30 years of experience, you can trust the team at Profile Mfg to guide you through the process including offering advice on sustainability and plastic suitability.

Schedule a meetingCUSTOM PLASTIC PROFILE EXTRUSION MANUFACTURER

Profile Manufacturing, Inc. is a minority owned and operated company. For more than 30 years we have been providing prompt service and quality parts to a variety of industries including automotive, marine, recreational vehicle, furniture, appliance, construction, solar, and packaging.

World Class Extruded Plastic Components

At Profile Mfg we understand our customers' needs for a reliable plastic profile supplier and for us this begins with quality and repeatability throughout the manufacturing process.

- We design and produce all extrusion tooling internally which shortens lead times, eliminates reliance on outside manufacturing, and reduces cost.

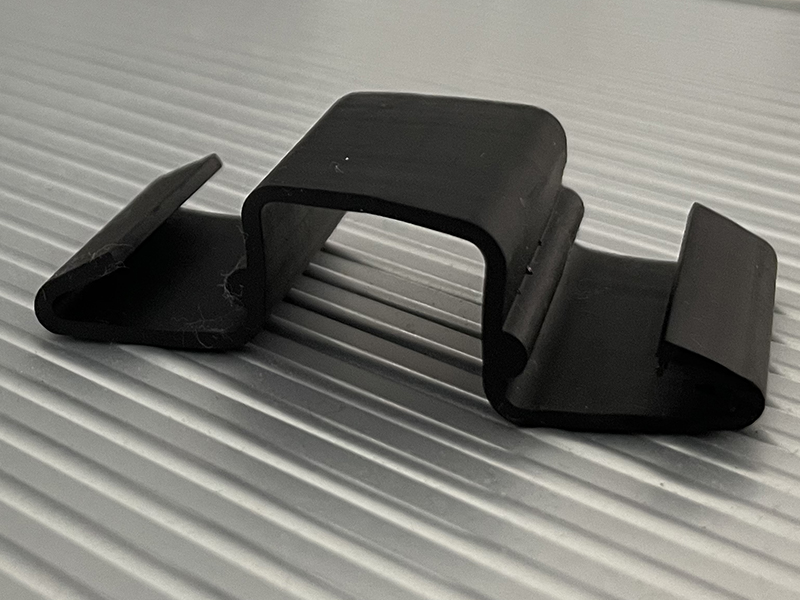

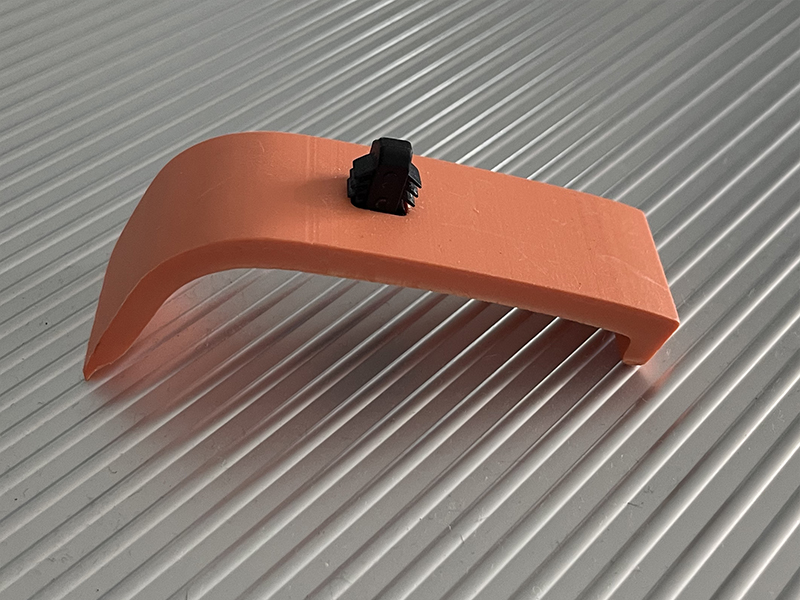

- We offer a variety of Secondary Operations to help reduce cost and shorten your time on getting your part to production. These secondary operations include end cap, die cut, heat forming, stretch bending, assembly, etc.

- The results of inline finishing of extrusion profiles is absolute precision, offering a maximum in cost efficiency and tolerance accuracy.

Value Added Products to Extrusion

Tape

Metal

Glue - Hot melt adhesives

Slip Coat

Flock Tapes

Graining

Mylar Films

Over Molding of Metals

Inline Finishing

A Few Companies Who Utilize Our Parts

Chrysler

Ford

Genreal Motors

Tesla

Mercedes

Steelcase

Rivian

Jaguar

BMW

General Electric

Canon

Quality Control. IATF 16949:2016 Certified

Through research and development, we reduce costs while improving the quality and functional characteristics of existing components and manufacturing processes. Our goal is to exceed customers' expectations.

Download our current Certificate of Registration.QUALITY POLICY

Profile Mfg is committed to provide superior products that meet or exceed the customers’ expectations.

CONSTANT IMPROVEMENT

We are dedicated to continual improvement of our quality system, customer service, and the highest level of ethics throughout the company.

ON TIME DELIVERY

It is every departments duty at Profile Mfg to insure each and every shipment meets it deadline.

SERVICE

Scientific design, sound engineering and responsive service make our products successful in applications for virtually every industry.

Industries

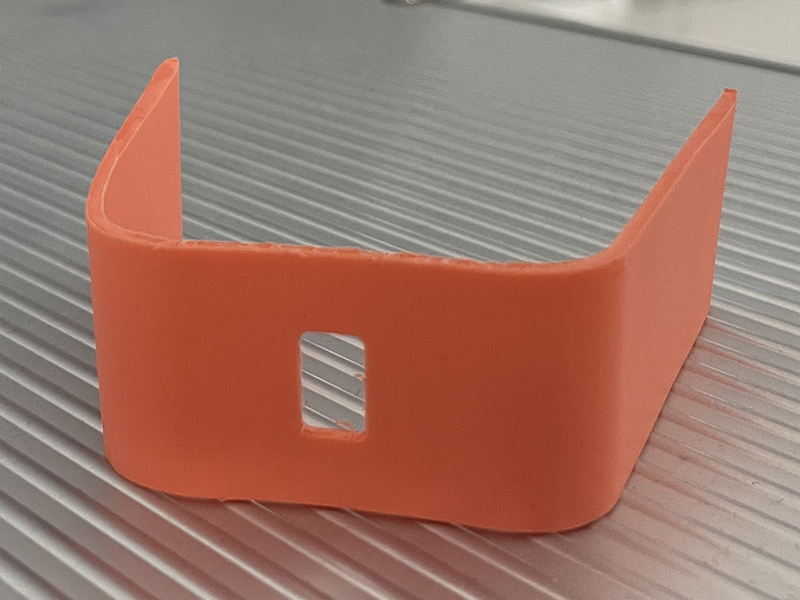

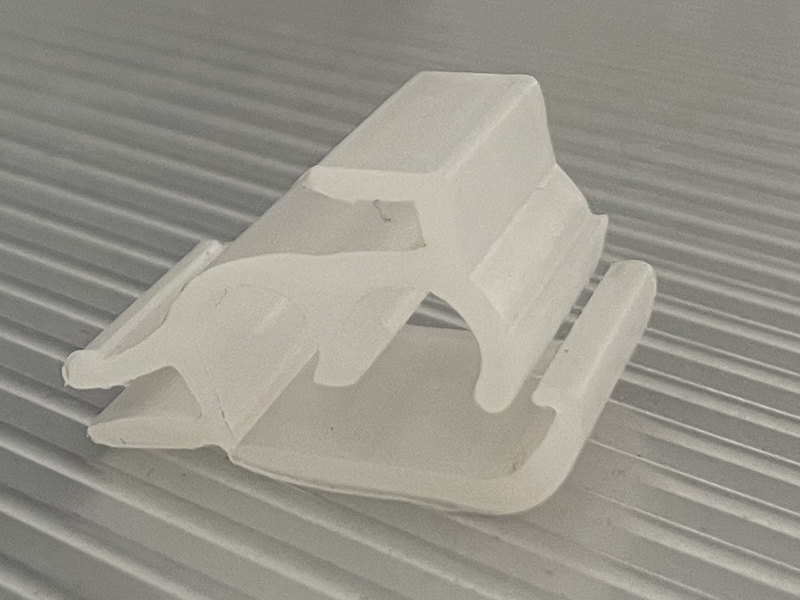

At Profile Mfg we extrude plastic profiles that are essential in the creation of a variety of products that serve a broad spectrum of applications and industries. Our capabilities facilitate custom plastic profiles in a range of configurations, sizes, thicknesses, colors, and lengths. Below are just a few of the industries we serve.

Automotive

From weather and UV protection to strength enhancement and sound damping, our products are located in very different areas of all world-known vehicle brands.

Marine

We manufacture marine extrusion profiles from a flexible, UV protected, plastic compound that will be durable enough to survive the rugged marine environment.

Furniture

Our plastic profiles increase process reliability in production, are used as connecting elements and help to provide specific contours

Appliance

Extruded plastics are sturdy and operational, making them a great material for the appliance industry.

Construction

Flame retardation, Energy saving and weather protection are just a few ways our parts are used in the construction industry.

Solar

Our durable plastic extrusions can hold up to the harsh elements such as wind, rain, snow, sun.

Departments

From engineering and design to quality control and our speedy shipping and delivery, Profile Mfg stands out as a top

CUSTOM PLASTIC PROFILE EXTRUSION MANUFACTURER.

Engineering

Profile Mfg has a fully equipped tool room with the latest three axis machining centres and wire eroders, which enable us to provide a complete in-house tool production and maintenance service to our customers.

Designing and producing all extrusion tooling internally shortens lead times, eliminates reliance on outside manufacturing, raises quality, and reduces cost.

Phone: (586) 598-0007

Email Tooling Engineer: Ken Nieman

Email Extrusion Engineer: Tim Smith

Quality

Our 30 years of experience manufacturing plastic extrusions has taught us that taking the time to consider the intricacies of extrusion design in the early stages of a project always achieves the best results.

A well-designed plastic extrusion will ensure cost-effective tooling, avoid production issues and reduce lead times from inception to delivery.

IATF 16949:2016 CERTIFIED

Phone: (586) 598-0007

Email: Susan Addley

VIEW QUALITY CERTIFICATION

Shipping & Delivery

Profile Mfg's lead-times and on-time-delivery are both best-in-class

With ever increasing demands by customers, we understand the need to have on-time and reliable deliveries along with proactive and responsive customer support.

Phone: (586) 598-0007

Email: Amy Chaffee

Accounts Payable/Receivable

Managing accounts payable and accounts receivable is essential to any business to ensure good relationships with suppliers and customers.

At Profile Mfg we think of our Accounts Payable/Receivable department as the PR team for your financial interactions. Please don't hesitate to reach out with any issues or concerns.

Phone: (586) 598-0007

Email: Lisa Yarema

Frequently Asked Questions

Extrusion is a process by which two dimensional shapes are produced from thermoplastic on a continuous basis. Pipe, tubing, sheet, solid shapes and profiles are typical extruded products. Any desired length part can be provided. In-line application of PSA tapes, labels, punching or notching are available on extruded parts.

- What is Profile Extrusion?

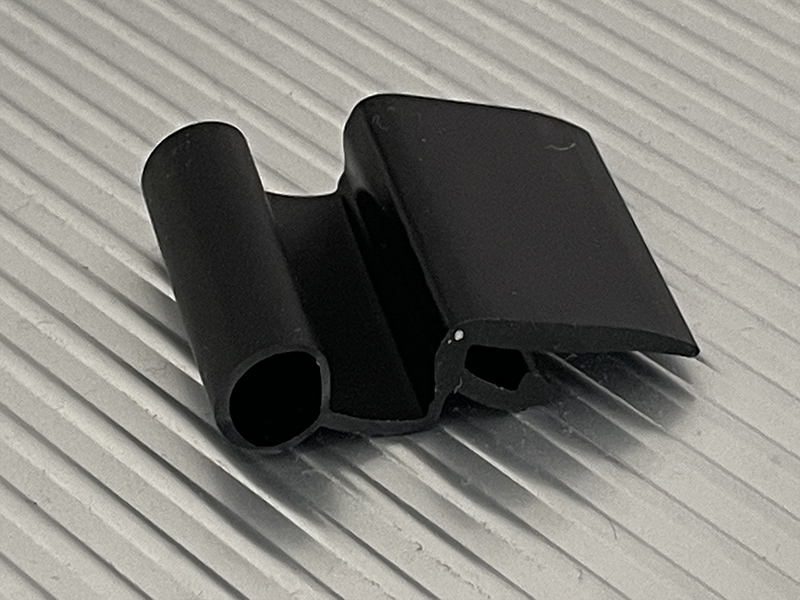

Profile extrusion is extrusion of a shaped product that can be a variety of configurations but does not include sheet or film products. Profile extrusion can include solid forms as well as hollow forms. Products ranging from tubing to window frames to vehicle door seals are manufactured this way.

- What are the limitations of extrusion process?

Typical tolerances for an extrusion are +/- 0.020 inches for dimensions up to 1.5 inches. Tighter tolerances are possible where necessary, but they can increase tooling cost, set up time or run speed - or all three. In most cases, +/- . 005 will be the tightest that can be effectively measured.

- If I wish to send an electronic drawing to you, what types of files can you accept?

We receive a wide variety of extrusion designs and file types to review each day. We can work with almost all of them. Ideally, a PDF file showing critical dimensions, tolerances and surface areas will help us understand the critical elements of your extrusion design. A CAD file will help us if there are any areas that are unclear and it can speed up the process of designing the extrusion die once you’ve placed an order.

- Why is extrusion better than rolling?

The extrusion process allows for a wider variety of intricate shapes compared to what can be produced through the rolling process. Additionally, extruded products have a higher quality surface and constant cross-section material throughout the length of the product compared to rolled products.

- What Quality Control Procedures Are Followed?

Profile Mfg is IATF 16949:2016 certified. Each product shipment is documented for compliance to strictest quality control guidelines, in addition to the nuances of the specific production run. Quality control is the responsibility of all Profile MFG employees and is monitored and recorded by Quality Assurance personnel on an hourly basis. We are routinely audited by major corporations for compliance to ISO standards and other recognized quality systems. Our consistently high level of product quality is the primary reason for our outstanding customer performance ratings and for our significant growth in the last decade.

- Can You Help With Material Selection Or Product Development?

Yes we can. Our staff has many years of experience in extrusion and we can provide some assistance to every industry that we serve. Our experienced team will help turn your concepts into quality products.

- How Do I Get A Quote?

You can get quotes in several ways: scroll down slightly and fill out our form, send us an email with your request or feel free to call us at (586) 598-0007 and talk with one of our engineers and we can discuss your needs and work up a quote from there.

Contact Us Today To Discuss Your Plastic Extrusion Requirements

From the initial design phase and development to production, our team of engineers are here to support you. Contact Profile Mfg today to set up a meeting to discuss your plastic extrusion requirements.